Additional information

| Brand | Formlabs |

|---|---|

| Weight | 10 kg |

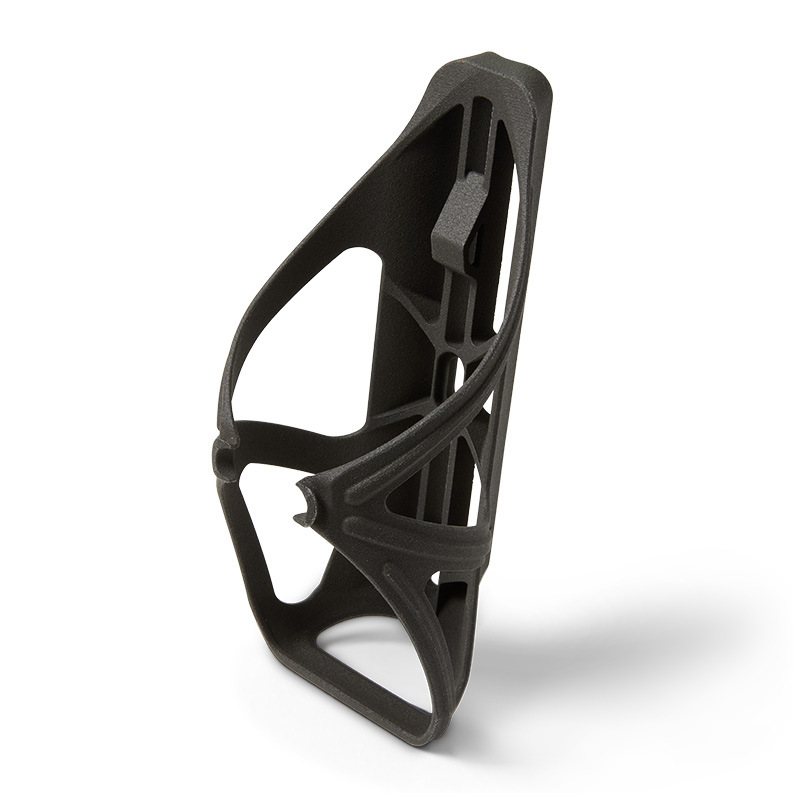

The ability to bend without breaking, yet still have enough structure to prevent sagging on its own, makes Formlabs Nylon 12 Tough suitable for:

- Levers

- Impact parts, shock absorption corners

- Shoe parts

- Holders that need to be bent open

Difference between Nylon 11 and Nylon 12 Tough

Formlabs Nylon 12 Tough is more similar to Formlabs Nylon 11 than Formlabs Nylon 12. Like Nylon 11, Nylon 12 Tough has a lower HDT-A temperature of 46°C, but it can absorb almost twice as much energy as Nylon 12.

The main difference lies in printability. Nylon 11 requires the 3D printing chamber to be completely filled with an inert gas. This can be achieved through a direct supply of nitrogen via a gas cylinder or a generator such as the FLAIRMO N2G-15C.

For Nylon 12 Tough this is not a requirement, which significantly reduces the cost per part.

3D Printer Compatibility

It is only possible to 3D print Formlabs Nylon 12 Tough with the more powerful laser module of the Formlabs Fuse 1+ 30W.

Bio-compatibility

- No systemic toxicity (ISO 10993-11:2017)

- Non-cytotoxic (ISO 10993-5:2009)

- Non-irritating (ISO 10993-23:2021)

- Non-sensitizing (ISO 10993-10:2021)

- Non-pyrogenic (ISO 10993-11:2017)

For easier sterilization, we recommend waterproofing parts via vapor smoothing.

Printing tips

Before first use, Formlabs Nylon 12 Tough requires “aging” at a specific printing temperature. You can find this process at the following link: Formlabs Nylon 12 tuning guide.

Our service engineers are always available if you need assistance with this process.