Formlabs has just released a new version of its Preform slicing software.

This version includes an update to a feature we at Fenix 3D really appreciate: applying texture and structure to the surface of a 3D model.

How does texture work on a 3D Model?

This is something that previously always required CAD software, and even then, not all CAD programs offered this out-of-the-box.

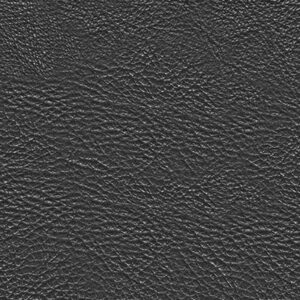

Applying texture to a 3D model (STL) works by wrapping a black-and-white image around it. Where a black pixel lands, the model is dented, and where a white pixel lands, it is dented. This image is called a “height map,” and the technique is called “displacement mapping“.

This means a user can create their own texture, for example, to resemble leather. It’s also possible to hide serial numbers and copyright techniques.

Selectively apply texture

Texturing was added in PreForm 3.41, but the texture was applied to the entire model, which was sometimes undesirable.

Version 3.48 now allows you to select faces of the model, so that, for example, only a handle is textured, leaving the rest of the design untouched. Doing this in the PreForm slicer makes prototyping even faster.

Less support mode

Also new in this version is an option to generate less support structure. This has the advantage of fewer contact points with the model, meaning less post-processing time to remove them. It will also slightly reduce the total printing time.

Let op: deze optie kan voor sommige modellen misprints veroorzaken, vooral als deze een hoog gewicht hebben.

More options for profiles

The Formlabs Form 4 printers feature multiple sensors to detect errors, one of which is located in the mixer. It’s now possible to adjust the sensor’s sensitivity to clumping and the mixer’s speed. This is especially helpful for companies that print the same object continuously, knowing the potential points of failure and saving additional time.