At Fenix 3D, we’ve been 3D printing for companies under the name CW Development since 2020. We specialize in Formlabs SLS and SLA, as well as FDM, for which we use Ultimaker and Prusa 3D printers.

Our Print Farm

Our current print farm consists of 7 Formlabs Fuse SLS printers, multiple Formlabs SLA printers, including large format that can print biocompatible material. We also are equipped with high-temperature FDM 3D printers capable of producing PEKK and PEI parts.

Security

We offer a standard NDA confidentiality agreement. Printed parts can be delivered within the Netherlands by our own courier service.

Full support

At Fenix 3D we also offer design and training services to help companies further develop concepts and start up initial prototypes and productions.

Contact us for a free quote or advice.

SLS 3D Print service

With our Formlabs Fuse 1+ print farm it is possible to 3D print parts up to 165 × 165 × 300 mm. The majority of these materials are also biocompatible and suitable for prolonged skin contact.

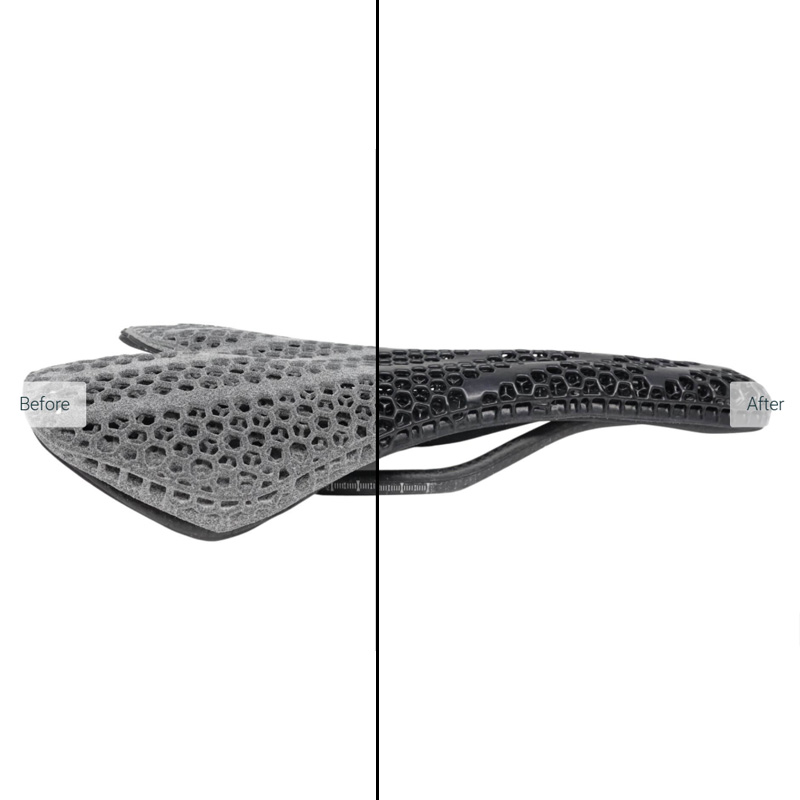

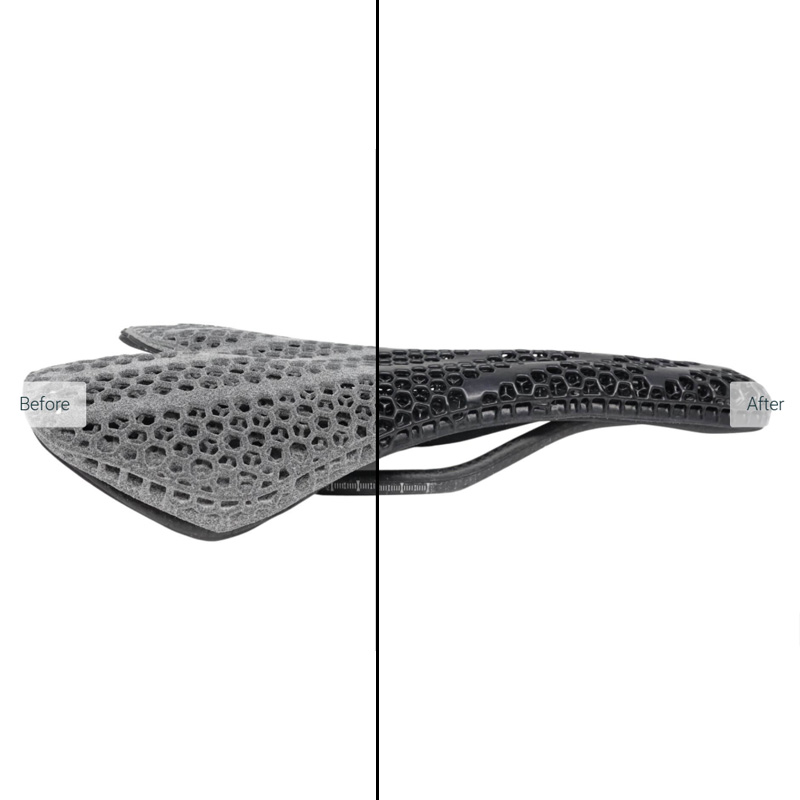

Flexible TPU SLS 3D Print Service

One of our most requested materials to print is Formlabs TPU powder. For “traditional” FFF 3D printing, it’s more difficult to print complex geometries due to material deformation. With SLS, this is much easier because the loose powder acts as support. With SLS, this is much easier because the loose powder acts as support.

TPU can also be made waterproof using our AMT machines, by vapor smoothing.

TPU SLS 3D printing is used for: Handles, shock-absorbing parts, ergonomic soles ….

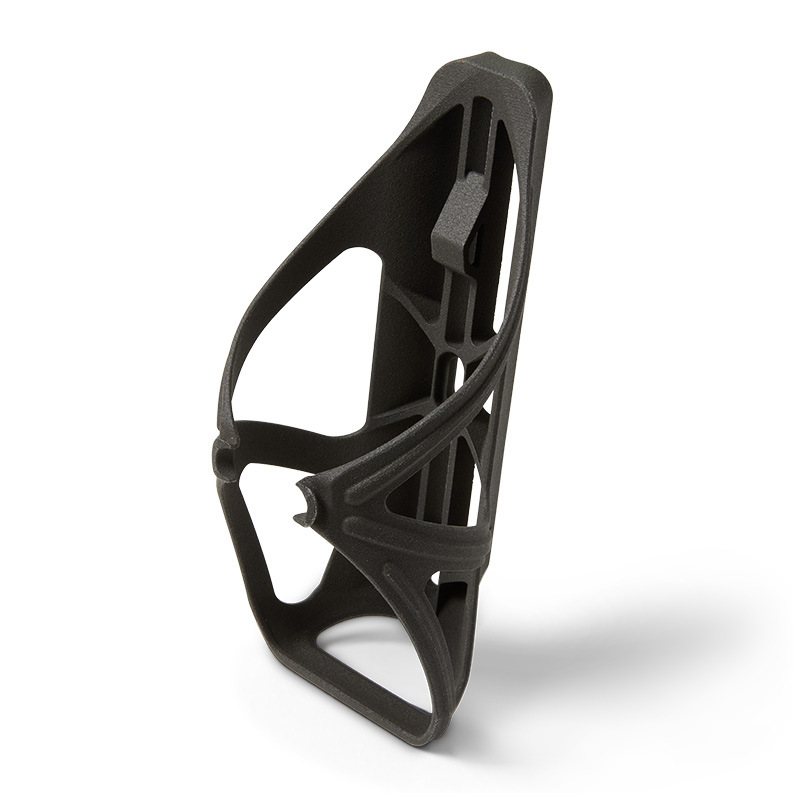

Polyamide / Nylon SLS 3D Print Service

A large part of the Formlabs catalog consists of nylon powders with different properties. These vary in hardness, flexibility (or stiffness in the case of fiber-reinforced PA). The exact properties of these

Examples of PA parts we have manufactured are: electronics enclosures, …

SLA 3D Print service

With our Formlabs Form 4 and 4BL printers, it’s possible to print up to 353 x 196 x 350 mm.

Biocompatible SLA 3d Print Service

Formlabs offers a wide range of biocompatible resins for dentistry, orthopedics, and surgery. These SLA resins are made in an ISO 13485-certified factory and are USP Class VI tested. For the exact required ISO certification and desired biocompatibility, please contact us.

Recurring print orders are for: molds for dental applications, orthopedic and sports insoles, orthoses and prosthetic parts, medical equipment parts, etc.

Flexible SLA 3d Printing

Besides flexible 3D printing with SLS powder, this is also possible with SLA resin. The advantage of SLA is that it allows for the creation of small, watertight parts with internal networks. At Fenix 3D, we offer hardnesses from 50 to 80 Shore A (comparable to rubber and leather). This can also be done with biocompatible resins.

SLA 3D printing is mainly used for: internal parts, seals or gaskets, and shock-absorbing parts for larger mechanisms.

SLA 3D Printing for Prototypes and Productions

Of course, it’s also possible to have standard SLA resins printed with us. These come in different flexibilities, high temperature and flammability resistances, ESD properties, and many more specific properties.

FDM 3D Print service

Besides SLS and SLA, we also work with filament FDM/FFF 3D printers in our print service. Here we can 3D print the most popular plastics such as ABS, PET up to 330 x 240 x 300 mm. Thanks to our filament partner FormFutura, it’s also possible to work with a specific RAL color from certain quantities.

FDM filaments are available with very varied properties, including the EN 4554-2 fire and smoke standard for train vehicles.

Filament 3D printing is especially suitable for: larger parts such as tooling….

Post-processing Options

After the printing process, it’s also possible for us to chemically vapor smooth and waterproof them, tumble them, impregnate color for white SLS powders, and paint them in any desired color.

Contact Us

Would you like us to brainstorm with you about your application or would you like us to produce your products? Contact us.

We are available by phone from 8:30 AM to 5:00 PM on weekdays: +31 (0)85-0045780